To support an assortment of applications in myriad industries such as automotive repair and manufacturing, air compressors are a necessary component. These enable the operation of tools like spray guns, nail guns and air wrenches. Additionally, they provide pressurized air for a range of processes. To aid in a better understanding of what they are, how they function and the types that exist, this article will delve into the world of air compressors.

Exploring the World of Air Compressors

A device that compresses power and stores it within a tank, an air compressor is the solution to transforming electricity into pressurized air. By utilizing an electric motor to drive a piston or turbine, the machine is enabled to effectively store the pressurized air until it’s needed for various operations or continuous tool usage.

When you need to purchase an air compressor, there’s an abundance of sizes to consider – varying from tiny units that you can fit right on the workspace, to larger-scale industrial equivalents. The magnitude of the air compressor you select is dependent on what kind of tasks you are performing and the corresponding tools being used.

Uncovering the Mechanisms of an Air Compressor

As the motor of an air compressor hums to life, air is steadily forced into a tank at higher pressure. This process is carried out by either a piston or a turbine, the former pushing the air through effective compression until it fills the space of the storage vessel. Then, this pressurized air is poised and ready to be used in a wide selection of operations.

The concept of air compression is uncomplicated; the air’s volume contracts, while its pressure ascends, as it is compressed. The intensity of air pressure is designated in pounds for each square inch (PSI), and the compressor engine can be tweaked to increase or decrease the force, depending on what is required for the job.

Kinds of Air Compressors

When it comes to choosing an air compressor, there is no one-size-fits-all option. Instead, the compressor you select should be matched to the tools you intend to use and the application for which it is being used. Popular types of air compressors include:

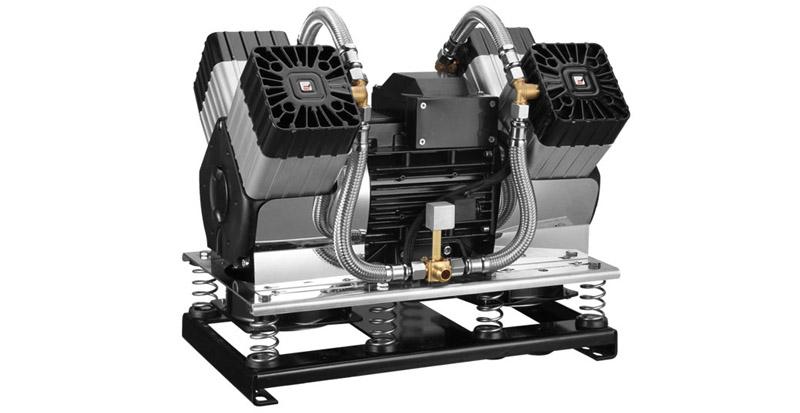

A piston compressor, otherwise called a reciprocating compressor, is a type of air compressor perfect for unpredictable applications, such as running a nail gun. The compressing and storing process is accomplished through a pistoning system which stores the compressed air in an attached tank.

• If you’re looking for a reliable, long-term source of compressed air, look no further than a rotary screw compressor! This type utilizes two intermeshed helical rotors in order to generate air pressure, allowing you to operate seamlessly for extended periods without requiring cooldowns in between.

This mode of compression operates on the power of centrifugal force, proving particularly suitable for industrial applications. It is capable of providing a plentiful delivery of compressed air in short order.

Lightness and size make this type of device perfect for bringing into remote spots; it is designed with portability in mind.

Utilizing Air Compressors for Your Advantage The use of air compressors can be of great help, offering a range of advantages such as:

Financially speaking, air compressors are often the most effective choice compared to other popular electricity and gasoline alternatives. With their sound economic efficacy, air compressors may make the difference when it comes to keeping your costs low.

Utilizing an air compressor for power needs proves to be much safer than alternatives, like gasoline or electricity, as a keyword of operation.

An air compressor presents a considerable degree of flexibility; it can do everything from filling up your car tires to enabling the use of specialized tools.

Air compressors are widely accessible; they are used in a broad range of settings, from the comfort of a private garage to the bustling environment of an industrial workplace.

For a wide range of applications in diverse industries, air compressors are an indispensable tool. Not only do they provide cost savings, safety, versatility, and convenience, they also power an array of machines and processes. With so many types available, selecting the most suitable air compressor for the job is key.

Possessing the power to transform regular energy into pressurized air, air compressors are multi-use devices that can be employed for a plethora of purposes. From powering air tools, to blowing up tires and providing compressed air for industrial operations, these equipment are becoming increasingly sought after, not only in the business world but also by homeowners.

An air compressor powered by electricity works by drawing in the surrounding air with a piston that moves in a cylinder. The piston is propelled by a motor that turns a crankshaft, and when it moves up, the air is compressed and stored in a storage tank. From here, the compressed air is ready to use for services such as powering tools or inflating tires.

A rotary screw compressor operates by forcing air into a chamber by two interlocking, helical screws. These screws are mounted onto an axis, twisting and spinning to compress the incoming air as they rotate. Highly efficient and capable of creating great pressure, rotary screw compressors are typically relied upon in industrial settings for larger-scale projects.

When it comes to portability, gas-powered air compressors have the edge. Perfect for use on job sites and at home, these machines provide a reliable and affordable way to enjoy the power of air tools. Whether you need it for DIY projects, woodworking, automotive mechanics, or something else entirely, a gas-powered compressor can get the job done in a claim and cost-efficient manner.

In order to facilitate a range of tasks, air compressors expel air from a storage tank where the air was previously drawn in and compressed. Regardless of the type, this process is generally repeated with any model of air compressor.

With the intention of buying an air compressor, one must consider a lot of aspects. Above all, determine the model of compressor necessary for your requirements. Different styles of air compressors are designed for dissimilar uses, so selecting the most appropriate one is pivotal.

When it comes to choosing the right air compressor, one of the most critical aspects to evaluate is its size. Portable models can be found in pint-sized dimensions, while those reserved for heavy-duty operations are typically large and stationary. The size of the compressor has a direct impact on the pressure it’s capable of producing, making bigger compressors more fit for industrial needs.

Ultimately, it is essential to contemplate the expense of an air compressor. The price for them can range from just a few hundred to several thousand dollars, depending on what type, size, and characteristics are included.

A perfect tool for various purposes and needs, air compressors remain a popular choice for many businesses and home owners alike. From running power tools to providing a gust to inflate a tire, air compressors are used in myriad ways. When purchasing an air compressor, it is important to think about the type, size and worth of the product to make sure that you are making the ideal investment for yourself.

Post time: 2023-07-24Related Product

Warning: Use of undefined constant rand - assumed 'rand' (this will throw an Error in a future version of PHP) in /www/wwwroot/www.sunritamachinery.com/wp-content/themes/msk5/single.php on line 69

15KW Mining Diesel Piston Air Compressor W2.8-5

Diesel Portable Piston Air Compressor Mobile for Jack Hammer / Mining 1.Simple structure,light weight,easy to move . 2.Easy operating and maintenance. 3.High quality air delivery. […]

20KW Mining Diesel Piston Air Compressor W3.2-7

Advantages Small in size,light in weight, easy to move Top material and superior technology Simple structure, high efficiency, good performance, and low price Adopt the most popula […]

20KW Mining Diesel Piston Air Compressor 2V4.0-5

Double Air Tank Diesel Portable Best-Selling Engine Oil Piston Air Compressor are mainly used to supply stable and clean compressed air to the pneumatic tools and keep them working […]

15kW Mining Diesel Piston Air Compressor W3.0-5

Diesel Portable Piston Air Compressor Mobile for Jack Hammer / Mining 1.Simple structure,light weight,easy to move . 2.Easy operating and maintenance. 3.High quality air delivery. […]

B37 Pneumatic Pick Air Shovel Cement Crusher Pneumatic Chipping Hammer

Product Description: B37 pneumatic crushing pick is a tool powered by compressed air. The compression the air is distributed to the two ends of the cylinder block in turn, so that […]

G10 Pneumatic Pick Air Shovel Cement Crusher

Product Description: The G10 air pick uses compressed air as the power tool, and the compressed air is distributed in two sections of the cylinder by the tubular distribution diver […]

S82 Air Leg Pneumatic Rock Drill Pusher Leg Rock Drill

Scope of application: Model S82 air-legged rock drills are heavy-duty air-legged rock drills with high efficiency and low consumption, which are especially suitable for use in the […]

YT29A Air Leg Pneumatic Rock Drill

Short Description: YT29A air-legged rock drills are heavy-duty push-leg (air-legged) rock drills with low energy consumption, which are more suitable for drilling horizontal or inc […]

B47 Pneumatic Pick Air Shovel Cement Crusher Pneumatic Chipping Hammer

Product Description: B47 crusher adopts the mature technology of American Gardner Denver Pneumatic Group Company,It is a crushing tool powered by compressed air, which can finish r […]